E Plug develops new tools for expansion of collapsed tubular

Challenge

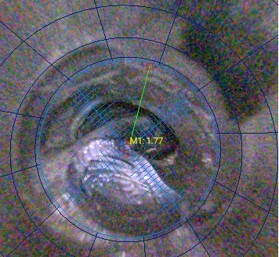

An operating company in the North Sea was facing the challenge with a collapsed section of their middle completion. They required a service to open the collapsed portion to obtain access to the wellbore below in order to evaluate further operations.

Solution

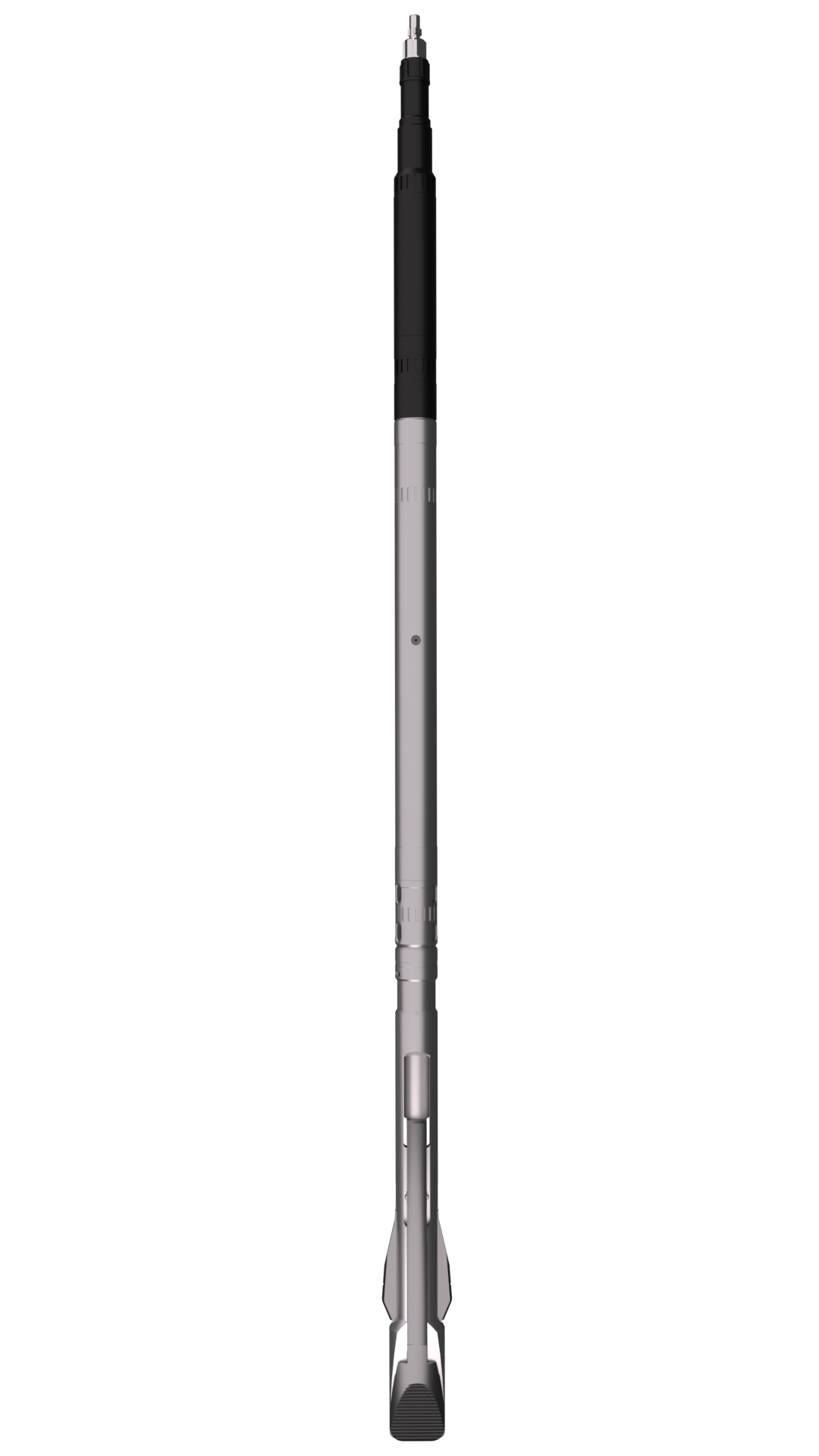

Based on the down hole camera footage E Plug developed 3 new tool designs based on the larger collapse expander tools for this smaller tubular. Two of these tool designs where different collapse expansion geometries, one symmetric and one asymmetric version, and the final tool was an orientation device that allowed for full 360-degree orientation of the tool string. The new tools were developed, produced, and tested in just 5 days, utilizing the functionality of the existing electric manipulation tool (EMT) and TorcDesperado. Applying the ability of the EMT to provide control of independent rotations and displacement using multiple manipulators enabled the creation of these new tools in such a short time.

The application of rotation, coupled with real-time sensor data supplied by the EMT, enabled the tool string to be oriented in the well bore before being run in hole to the point of interest. Several expansions were made by displacing the center cone relative to the expansion pads of the tools. As these operations were conducted in a highly deviated well bore, the bottom hole assembly also consisted of a tractor and stroker from a 3rd party service company. This allowed the expansion bit to be re-positioned by using the stroker to grip and displace the bottom part of the tool string into the collapsed area.

When the collapse had been opened, the tool were set at the desired diameter and used as a selectable drift in being pushed through the expanded area with the stroker. The tools were then brought back to the surface, and the OD of the tool string was verified to 3,68", which gave the customer a confirmation of what had been drifted down hole.

Value Created

By enabling the customer to regain access to the lower wellbore, the operation provided the opportunity to continue operations with this new subsea well.