From 7 runs to 1: TorcPlug Enhances Efficiency in Well Completion

Challenge

A North Sea Operator needed to perform several operations during their upper completion phase before putting their well into production. This scope included integrity testing of the upper completion, setting the hydraulic set production packer, inflow testing the downhole safety valve, and installing a temporary barrier.

To complicate the matter, there was a glass plug already installed in the lower completion, and its pressure integrity was lower than the pressure required for testing the upper completion.

Solution

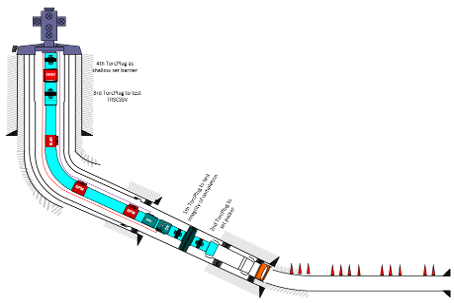

The TorcPlug from E Plug was chosen with an integrated pressure and temperature gauge. A contributing factor for choosing the TorcPlug was the ability to perform all four operations in one single run.

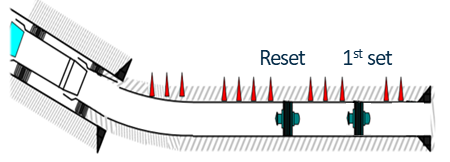

The first stage was to test the integrity of the upper completion. With the pressure and temperature system below the TorcPlug, the customer had full control over any pressure leaking past the plug, towards the glass plug. This made sure the pressure test of the upper completion could be performed in a safe and reliable manner.

The next step was to move the plug further down and set the production packer. Once this was done, the plug was repositioned to inflow test the downhole safety valve. Finally, the TorcPlug was installed as a temporary barrier.

Value Created

Instead of needing seven separate runs to complete these operations, the TorcPlug was able to perform all of them in one single run. This reduced rig time by 60 %.

In addition, the real-time gauge eliminated the risk of the glass plug accidentally bursting. It also confirmed that the TorcPlug was set correctly and completely sealed before they applied pressure or installed the production packer.

The customer had much better control of the process, thanks to the TorcPlug, and saved both rig time and operational cost. They also reduced risk by choosing this product.