Successful TorcPuncher Operation on the Norwegian Continental Shelf

Challenge

A North Sea operator required a safe, efficient, and non‑explosive method to create tubing‑to‑annulus communication as part of their well Plug & Abandonment (P&A) program. The objective was to perform multiple punches in a single run while ensuring full real‑time verification and minimal operational risk.

Solution

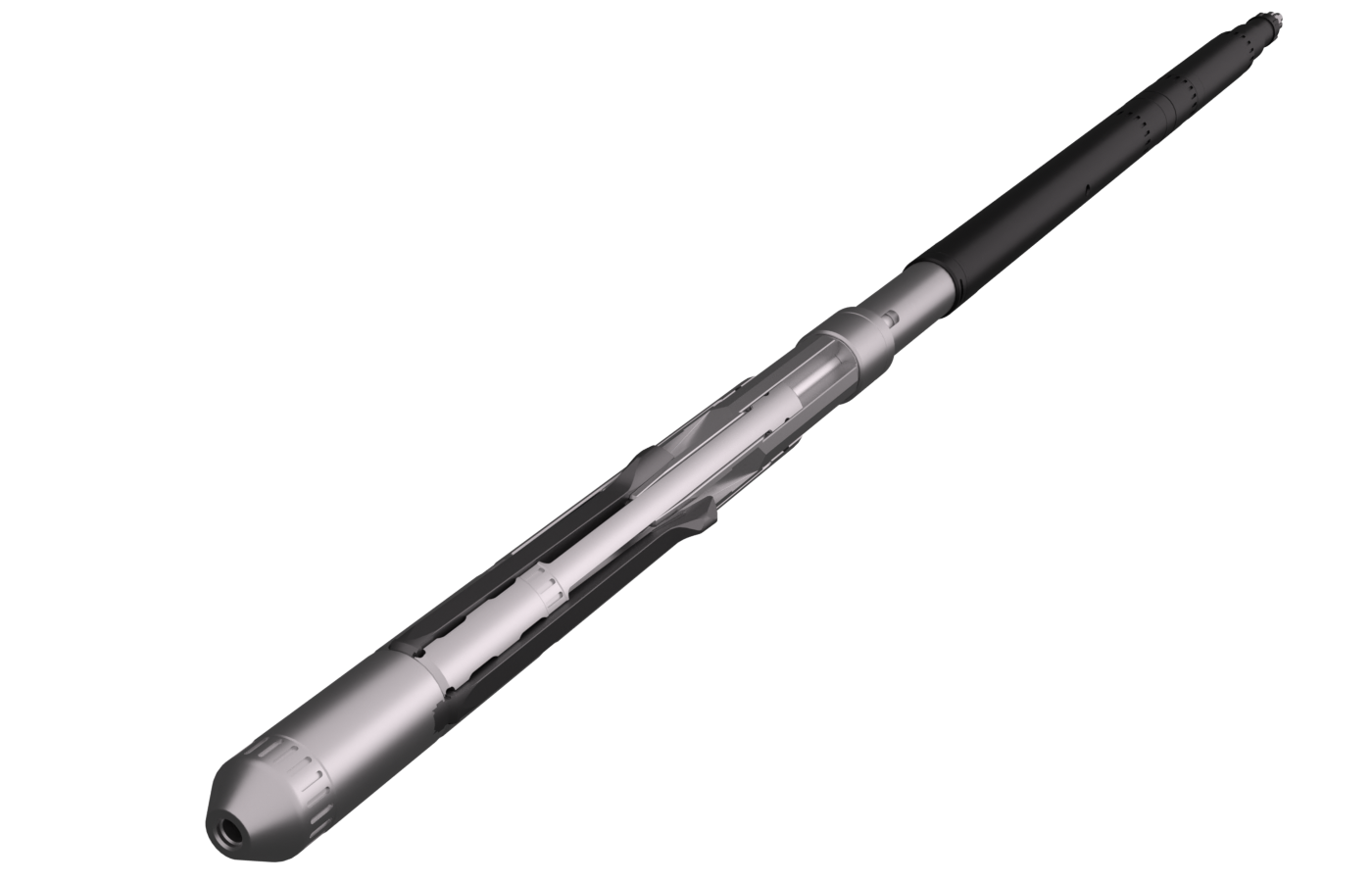

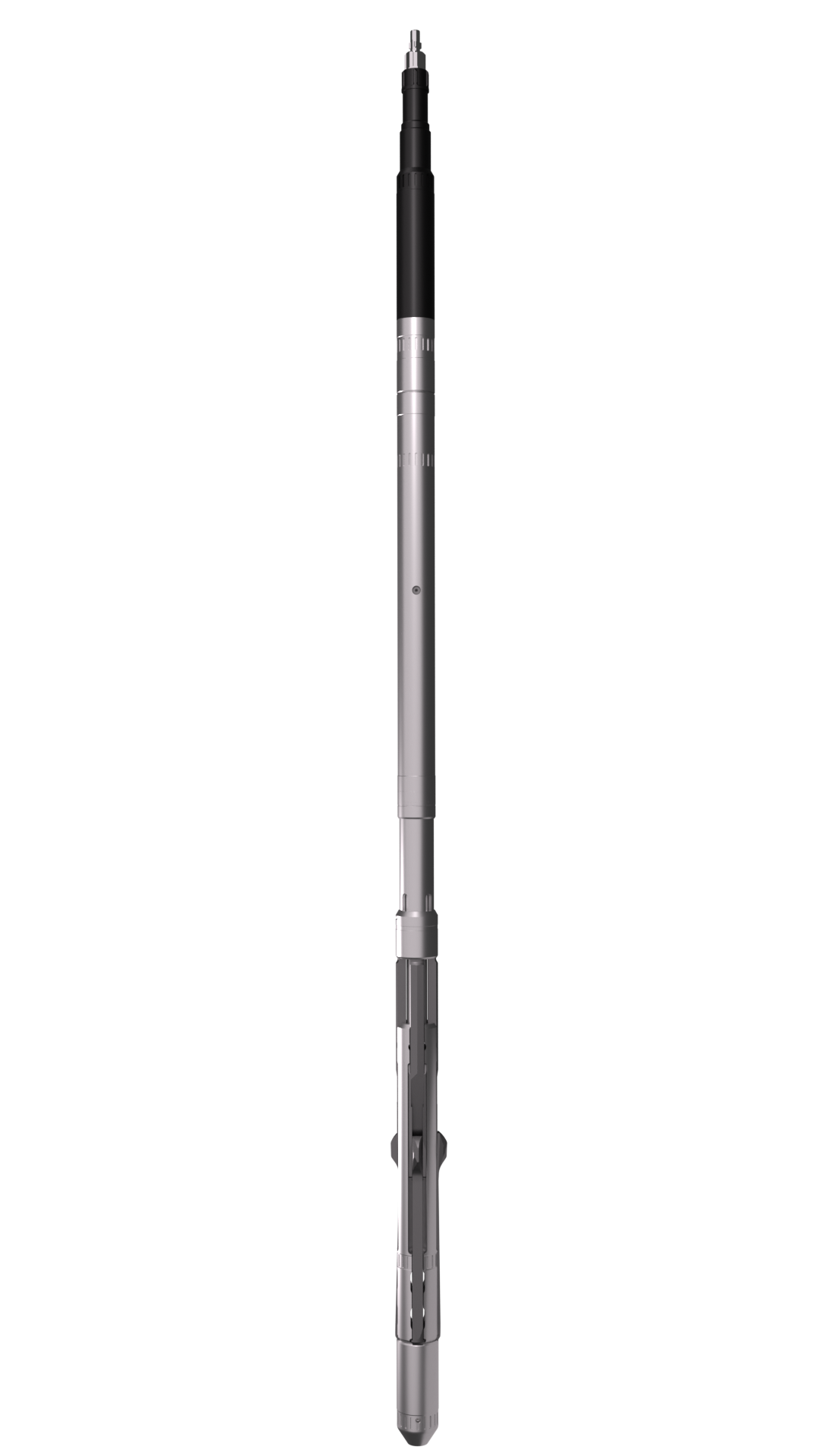

The Solution was the TorcPuncher an Electro-Mechanical Punching System from E Plug, powered by the EMT and TorcDesperado actuator, enabling fully controlled, real‑time‑verified mechanical perforation.

Key features & benefits:

- Non‑explosive, electro‑mechanical activation – eliminating dangerous goods.

- 360° coverage enabling multiple punches in a single run.

- Real‑time signatures confirming penetration, deformation, and retraction.

- Controlled deformation creating clean, uniform openings.

- Rig‑less P&A‑ready system for reduced cost and operational exposure.

Execution

Value Created

The TorcPuncher proved to be a safe, reliable, and highly effective solution for the North Sea P&A operation.

Its electro‑mechanical precision, real‑time verification, and multi‑activation capability delivered a clean and repeatable result—helping the customer achieve their abandonment objectives with confidence.

The entire operation, from deployment to recovery, was successfully completed efficiently within 12 hours. The tubing was retrieved later and result was confirmed.