Non-Explosive Casing Punching

Increased Total Flow Area achieved with a single activation

Challenge

A Middle East operator faced a well integrity problem when a slow leak of CO2 into the A1 annulus occurred. This caused pressure to build up and increased the risk of corrosion in the production casing when the well was converted into a CO2 injector.

Their goal was to punch the tubing to create a pathway to the tubing's annulus and bullhead its contents into formation. The punching process needed to be carefully managed to prevent damage to the outer casing. Additionally, there was a need for a TFA that could enable pumping at a sufficiently high rate.

The well's location and the risks associated with using explosives made it unsuitable, so an alternative method was needed.

Solution

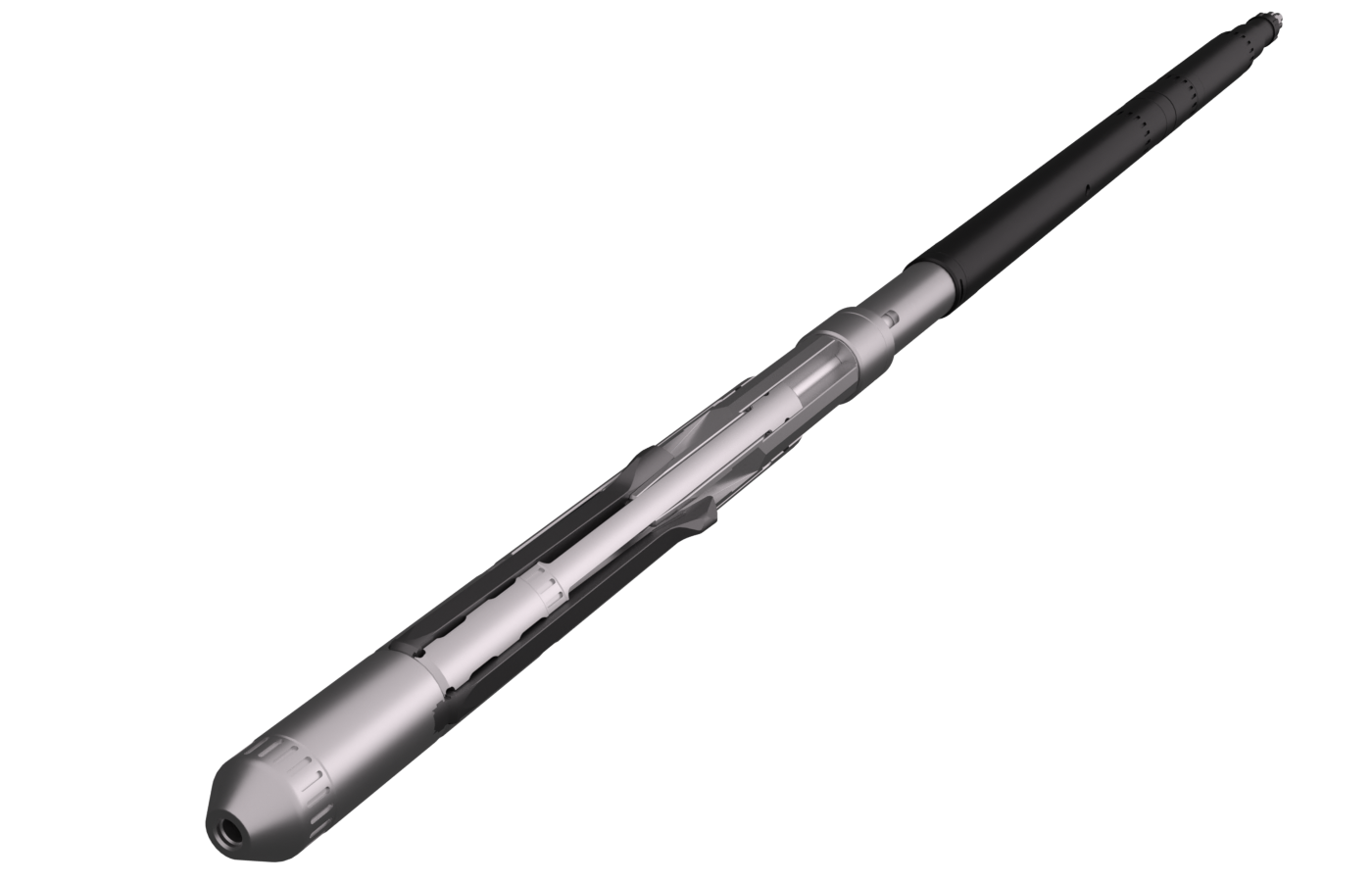

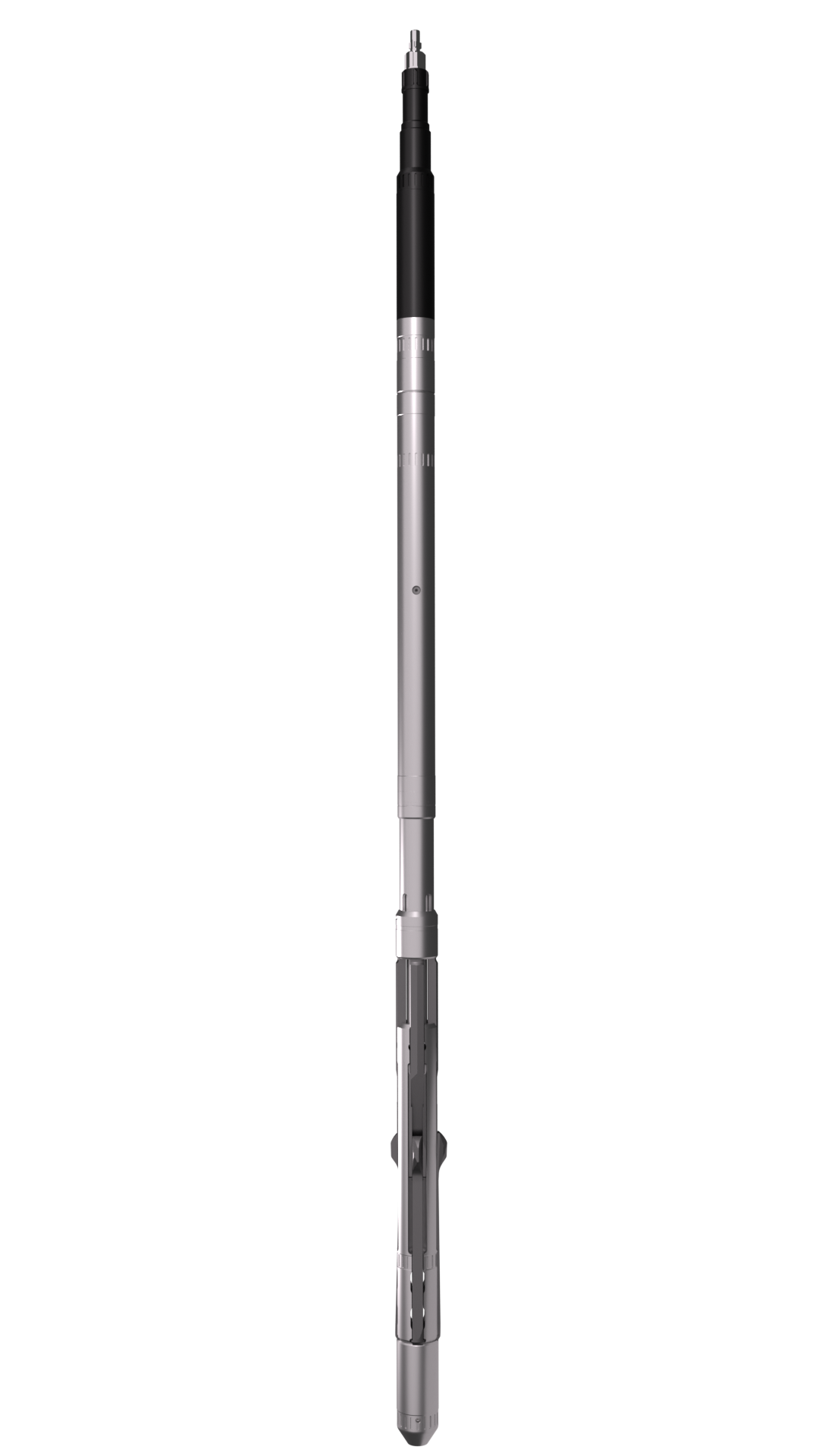

The TorcPuncher tool was recommended to the client as a purely mechanical tool, with the running tool (Electric Manipulation Tool) providing real-time control for a controlled punch and enlargement of the punched holes.

A test punch was performed on a piece of casing at the rig site to measure and calibrate the tool's performance, ensuring that the planned TFA was achievable. This demonstrated to the client the controllability and real-time decision-making ability of the solution.

The tool was run to the planned depth on e-line in a rigless operation, and the tool was activated. After completing the punch sequence, the blades were retracted, and the tool was pulled up 100 ft above the punched area. The annulus was bullheaded to confirm that the single activation had achieved the desired result, and the tool was pulled out of the hole.

Surface Verification of the 4 hole being made by the TorcPuncher

Punched tubing retrieved from well.

Value Created

The customer achieved the desired result with a mechanical solution in a single activation.

This method avoided the use of explosives and saved time and money over other alternative methods, one of which required approximately 19 tool activations to achieve similar results.

The tried-and-tested TorcMethod provided the control needed to deliver an exceptional performance.